Published on the 22nd August 2024 by ANSTO Staff

Key Points

- Annealing above 150° C affected the vertical structure of bulk heterojunctions (BHJs) with a non-fullerene acceptor (ITIC) and caused structural instability

- Findings clarified how different phases interact in BHJs and can guide improvements for the thermal stability of non-fullerene acceptors in energy conversion devices

- Neutron reflectometry revealed nanoscale characteristics in the thin film

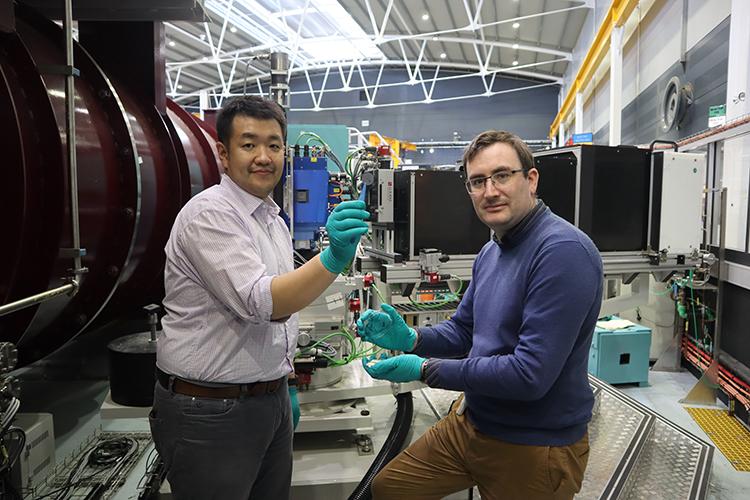

A large international team led by scientists from the National Synchrotron Radiation Research Centre in Taiwan in collaboration with research groups in Germany from have provided an understanding of how nanoscale interactions affect the thermal stability of a type of next generation organic solar cells in research reported in ACS Applied Nano Materials.

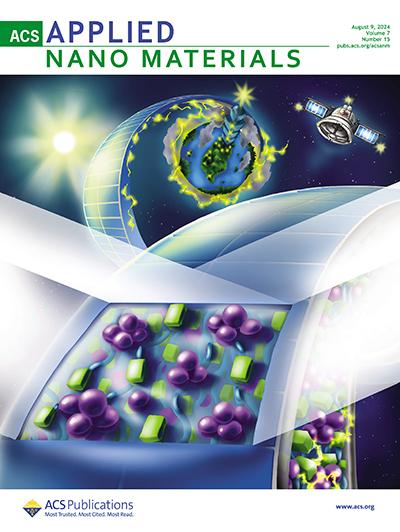

The research was featured on one of the covers of the journal.

Organic solar cells (OSCs) have numerous advantages, including flexibility, light weight, manufacturing economies, a wide range of applications, less environmental impact and semi-transparency.

However, energy experts suggest there is a need for an increase in efficiency, as well as an improvement in long-term stability.

Bulk heterojunctions (BHJs), a blend of electron donors and acceptors, need methods to optimise their structure at the nanoscale.

“The material tested in this study was a blend of a reputable polymer donor PffBT4T which provides good device performance and a new generation non-fullerene acceptor, ITIC, which was known to cause a performance drop,” explained Dr (Ian) Tzu-Yen Huang, lead author.

The blended material, which was tested in different concentrations of the donor and acceptor materials, is only tens of nanometres thick, approximately 1,000 times thinner than a sheet of A4 paper.

Thermal annealing, heating up the material during manufacture, is done to improve the performance of a BHJ.

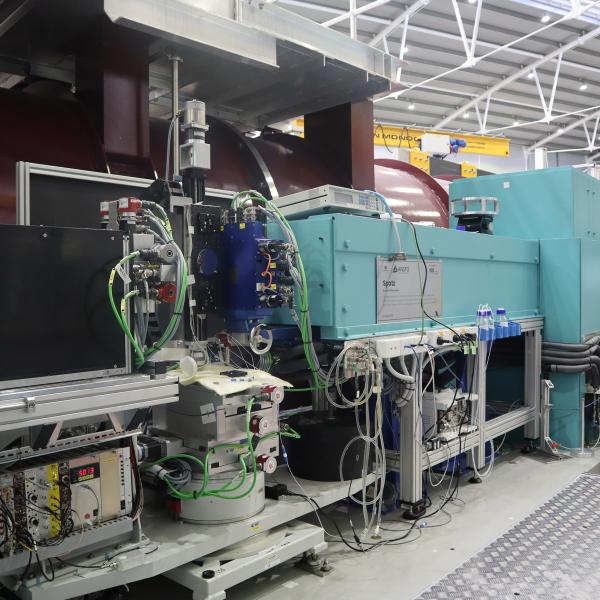

Measurements on the Spatz neutron reflectometer at the Australian Centre for Neutron Scattering revealed how annealing above 150° C affected the vertical structure of the BHJs and caused structural instability.

Thermal annealing made the interface of the BHJ thin films more diffuse at the interface in the ITIC molecules, increased aggregation in the ITIC and film roughness.

‘In other materials, the polymer can dominate the nanoscale interactions, but this is a special case, in which it is the ITIC.”

Additionally, ITIC molecules stacked in a terminal function group arrangement on the surface of the thin film.

The team suggested that initial poor mixing of ITIC also contributed to its instability during annealing, which could affect energy conversion efficiency and device stability.

“Neutron reflectometry can measure the thickness and density of different layers within a thin film. This depth profiling helps in understanding how materials are distributed within the film, explained Senior Instrument scientist Dr Anton Le Brun, a co-author.

It is one of the first papers using Spatz, an instrument transferred from BER-II Research Reactor to ANSTO under an agreement with Helmholtz-Zentrum Berlin in Germany.

Scientists from Deutsches Elektronen-Synchrotron DESY and the Technical University of Munich had access to Spatz and began a collaboration with Dr. Huang, after finding a shared interest in materials for organic solar cells.

“These findings help us understand how different phases interact in BHJs and can guide improvements for the thermal stability of non-fullerene acceptors in energy conversion devices,” said Dr Huang.