Defence and aerospace

Defence requirements push your technology.

We can help.

ANSTO is home to some of Australia’s most important landmark research infrastructure – more than $1.3bn of it. Our unique capabilities are used by thousands of Australian researchers from industry and academia every year.

Drawing on more than sixty years of materials, engineering, and environmental research, since the days when it was known as the Australian Atomic Energy Commission, ANSTO has developed a unique set of facilities and expertise well aligned with the needs of the defence sector.

Read our Defence and aerospace brochure

Case Studies

Critical weld failure

Challenge

Predict weld failure in critical components

Solution

Non-invasive residual stress analysis using neutron scattering

Modelling armour and blast resistance

Challenge:

Accelerate armour development

Solution:

Sophisticated computer and measurement-validated simulations

Engineering for critical components subject to unusual conditions is an area of expertise that ANSTO has developed as Australia’s authority in nuclear technologies and only operator of nuclear reactors.

Advanced metal and ceramic components

Challenge:

Optimise strength in sintered materials

Solution:

De-voiding and densification with HIP process Synroc

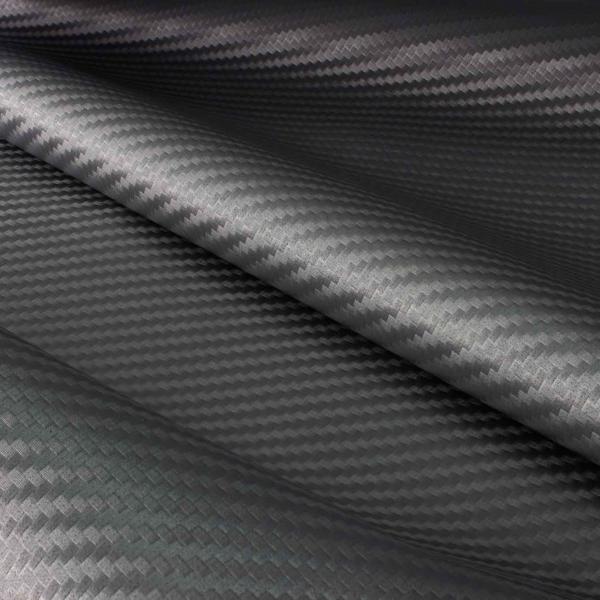

Carbon fibre manufacturing

Challenge:

Improve pre-carbonised fibre

Solution:

Synchrotron infrared mapping of carbon-nitrogen bonding

Manufacturing techniques for advanced materials require specialized knowledge and facilities not commonly available. ANSTO’s experience in developing SYNROC technology offers new solutions.

Manufacturing the most advanced piezoelectric materials for new SONAR applications or utilizing the most sophisticated Hot Isostatic Pressing (HIP) facility in Australia to strengthen 3D printed components.

Laser cladding metal surfaces

Challenge:

Assess new process

Solution:

Synchrotron elemental mapping of alloy and parent metals in coating

Critical weld failure

Challenge

Predict weld failure in critical components

Solution:

Non-invasive residual stress analysis using neutron scattering

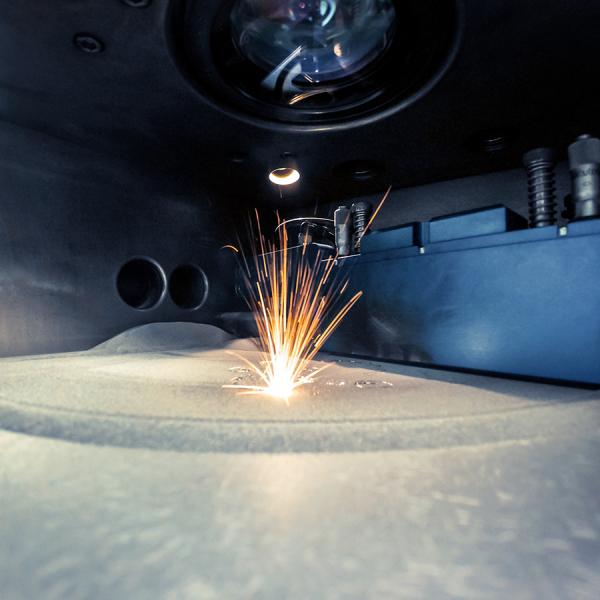

Complex 3D metal printing

Challenge:

Improve 3D print

Solution:

Synchrotron 3D X-ray imaging of part at micron resolution for non-destructive internal inspection and process optimisation

Materials at the most basic level define what a component can do and how long it will last. The Australian Centre for Neutron Scattering and the Australian Synchrotron can provide tools that can help solve materials-based problems when more conventional testing techniques are not enough.

Understanding why a polymer composite is degrading, how a metallic coating can be improved for longer life or when a complex 3D component build is failing can require the use of infrared, x-ray and neutron techniques.

Testing

Testing the resistance or hardness of electronic components and systems to different kinds of radiation to gauge their suitability for vehicles and satellites in low and high earth orbits - as well as deeper space missions.

Collaboration

Collaboration with industry and academia is fundamental to our relevance. As an example, the ANSTO Innovation Precinct co-locates a community of industrial users with ANSTO infrastructure at Lucas Heights, NSW.

Nandin, the heart of the Innovation Precinct is home to a community of researchers, students and startup companies dedicated to a number of challenges relevant to the defence sector. To complement this, the newly-formed ANSTO Graduate Institute will further assist early career talent in Australia by co-developing graduate project proposals with Australian Universities.

Security

Security of intellectual property and the capability of accommodating higher security classifications are built into the structure of ANSTO.

ANSTO enjoys the best of both worlds – secure and ISO accredited research sites, as well as long-standing collaboration with DST, CSIRO and Australian Universities.

Enquiries

Have a question? Get in touch with our team.

Sandy Haig