Centre for Accelerator Science

Overview

The high energy heavy ion microprobe is a unique scientific instrument, which is coupled to an accelerator system to produce a highly focused beam of accelerated ions with a spot size down to the sub-micrometre dimensions – ion microbeam.

The (heavy) ion beam produced by a tandem accelerator is focused by a system of electromagnetic lenses similarly to focusing the light using a system of optical lenses like in a camera. The object is a beam passing through a tiny rectangular aperture that is far away from the lens system compared to the aperture size. The microprobe is essentially an inverted microscope that uses a focused beam of accelerated ions with energy in the MeV range as an imaging probe.

The ion microbeam is defined by the ion type, energy, and charge, as well as the microbeam current in a given spot size area (the current density or the ion flux).

The microprobe is a tool for bulk, the direct opposite to the electron or low-energy (keV) ion microscope that is a surface imaging (probing) tool. It is used for the characterisation or modification of material properties at depths from approximately 1 micrometre to maximum depths of up to 500 micrometres from the material surface. The selection of ion type and energy is guided by the required probing depth in material/sample/target.

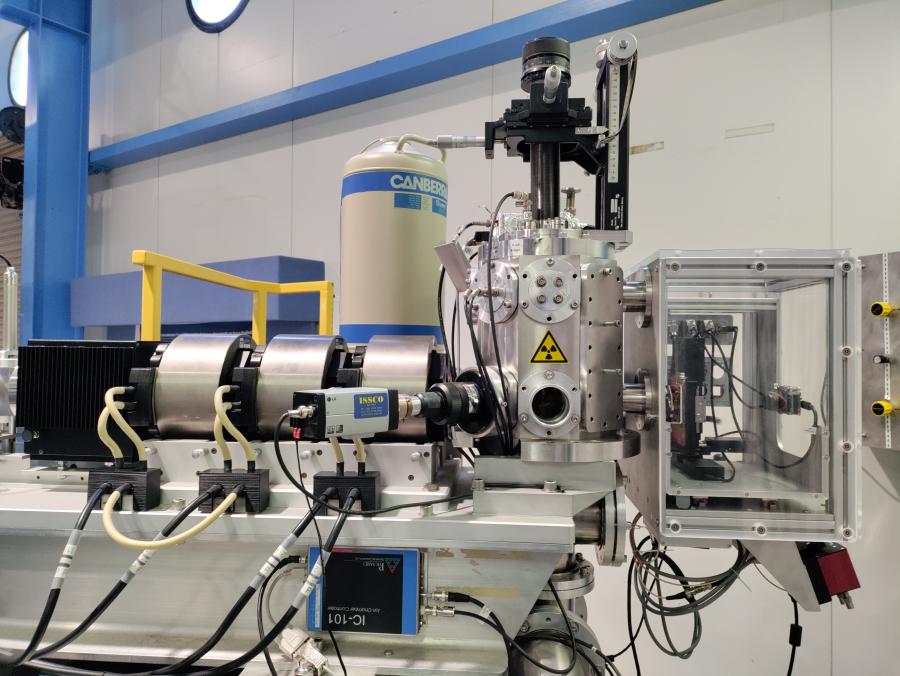

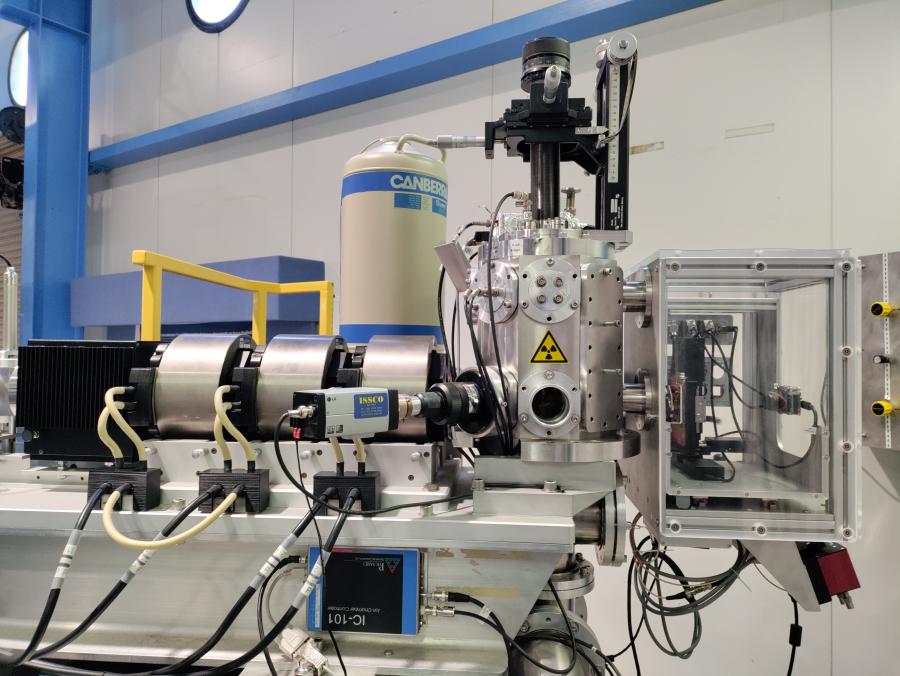

ANSTO Heavy Ion Microprobes

The Centre for Accelerator Science houses 2 heavy ion microprobe beamlines on the 10MV ANTARES and 6MV SIRIUS accelerator, designed to focus ions of the most elements from the hydrogen up to lead. The main parameter defining the focusing capability of a microprobe is the magnetic rigidity (the product of the ion mass and energy divided by the square of ion charge).

The ANTARES heavy ion microprobe is a unique instrument, among only a few microprobes in the world that can generate the focusing magnetic field of 1 Tesla and higher in each lens, reaching a maximum rigidity of about 120 amu*MeV/e2 , compared to the SIRIUS microprobe capable of maximum rigidity of 38 amu*MeV/e2.

Technical Specification:

| ANTARES Heavy Ion Microprobe | |

|---|---|

| Maximum Rigidity | 120 amu*MeV/e2 |

| Focusing system: | Oxford Microbeams triplet lens |

| Beam spot size: | 1-6 µm (depending on ion beam brightness) |

| Magnetic beam scanning: | ~ 50 - 3000 µm (X, Y) |

| Positioning or scanning accuracy: | ~1 µm (X, Y, Z, R) |

| Automated object and collimating slits accuracy: | ~100 nm aperture |

| Optical microscope for imaging: | 40X |

Ion microbeam delivery

The modern computer-controlled microprobe allows:

- Scanning resolution between 32 - 1024 pixels (X, Y)

- Pixel dwell time between 200 µs – 1 s

- Rapid raster-scanning of ion microbeam over a sample surface

- Sample scanning using a high precision sample stage movement combined with a stationary ion microbeam

- Hybrid scanning using a high precision sample stage movement combined with a monodirectional rapid raster-scanning of ion microbeam

- High-accuracy targeting of ions for implantation, or

- Customized beam current, particle rate, flux, or radiation dose for irradiation of targets on any kind (electronic devices, advanced materials, biological samples).

Microprobe capabilities

The ion microprobe is particularly useful to analyse or fabricate samples with a microstructure. The high-resolution scanning ion microbeam is generally used to investigate the non-uniformities in elemental composition or other material properties in samples that occur on the micrometre scale in two dimensions.

A combination of the high two dimensional (2D) position sensitivity of the scanning microbeam with the depth sensitivity of ion beam analysis (IBA) techniques makes the three dimensional (3D) elemental profiling or target material investigations possible.

Furthermore, the temporal dimension can be added to the microprobe probing capability by using a pulsed ion microbeam or a detection of the single ion arrival to a target or hitting a target. This allows the deterministic 4D single ion implantation and studies of dynamic processes in a material or an electronic device following the single ion impact.

Two groups of microbeam capabilities are distinguished by the ion microbeam current value. The low current capabilities are characterised by the microbeam current well below one picoampere (1 pA). The ion beam is a steam of well-distinguished (detectable) ions by means of fast electronics used for detection of a signal induced by the single ion interacting with a target or something else before hitting the target. Instead of the microbeam current, the microbeam ion rate or ion microbeam frequency is specified and it is usually in the 100 Hz-100 kHz range. This type of ion microbeam is used for the 4D imaging of material properties or deterministic 3D single ion implantation for fabrication of advanced electronic device prototypes.

The other group is high current imaging IBA capabilities. The majority of IBA techniques rely on atomic processes that are characterised with a small cross section (probability for occurring). Therefore, they use the high current microbeam that is usually of the order of hundreds of picoamperes (100 pA) to achieve a sufficient number of detected events for imaging purposes. The highest beam current density (beam brightness) for a specific ion type that is produced at the object aperture of a microprobe by a given accelerator system is the main limiting factor for the highest microbeam current that can be achieved in a desired spot size. The higher resolution for IBA imaging is required, the microbeam current is lower, and the corresponding data recording time is longer.

| Low current or single ion imaging IBA techniques | High current IBA techniques suited for microscopy |

|---|---|

| scanning transmission ion microscopy (STIM) | particle-induced X-ray emission (PIXE) |

| secondary electron microscopy (SEM) | Rutherford backscattering (RBS) |

| ion beam induced current (IBIC) microscopy | Nuclear reaction analysis (NRA) |

| Elastic recoil detection analysis (ERDA) | |

| Forward scattering |

External ion microbeam

The external ion microbeam can be extracted from the vacuum where it is produced and injected into an ambient environment through a very thin membrane (500-1000 nm) without compromising the ion direction, the ion energy, or the beam current/density. The ions will experience a small energy loss or a small deviation from initial direction (straggling) before hitting a target. These effects are usually negligible for the light ions, but special care has to be taken in designing the external beam capability for heavy ions.

The external ion microbeam (or just the external microbeam) allows experiments in the fields of radiation biology and applied physics that couldn’t be performed in a vacuum —including the irradiation of human cells and other biological samples.

The methodology of irradiating biological samples using the ion microprobe

The main advantage of using the external ion microbeam for a radiobiology experiment is that the cells are preserved in their natural liquid medium at atmospheric pressure and room temperature.

The heavy-ion microprobe equipped with the system for beam extraction is used to deliver a beam of high-energy (heavy) ions with a required radiological dose rate for the irradiation of a cell culture or tissue. The radiological dose rate is calculated from the ion specification (M, E, Q), the ion flux, the ion energy loss rate in target and the thickness of a target, and can be adjusted over a large dynamic range using customised microprobe settings.

Advantages of using the external heavy ion microprobe for radiobiology studies:

- Tuneable ion energy loss rate

- Tuneable ion flux

- Tuneable ion range

- Homogenous ion flux.