Published on the 7th June 2019 by ANSTO Staff

The difference between an RBMK reactor and the OPAL reactor

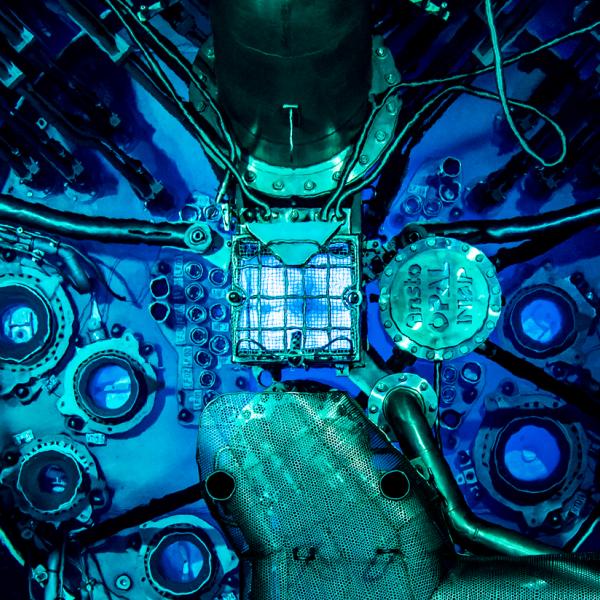

OPAL is a 20MW (thermal) multipurpose research reactor designed for making medical radioisotopes but which does not produce electricity. The OPAL reactor uses ordinary ‘light water’ to do a number of things: to cool the reactor, to moderate neutrons (i.e. enhance fission reactions and maximise the use of uranium fuel) and to shield personnel from ionising radiation. OPAL has an unpressurised core with 16 fuel assemblies containing 37 kg of uranium in total.

The Russian RBMK is a much larger reactor operating at 3,200 MW (thermal) / 1000 MW (electric). The pressurised core contains 1661 fuel assemblies with 192,000 kg of uranium. Unlike OPAL, the RBMK uses a mixture of materials in the core: light water for cooling the reactor core but graphite to moderate neutrons. It does not have any provision for containment of the reactor in the event of a hazardous event.

Using a mixture of water and graphite in the core increases the operational complexity of RBMKs, which in part contributed to the Chernobyl accident. The fact that the RBMK is a boiling water reactor adds a further degree of complexity. A sudden increase in reactor power in the RBMK could result in water boiling in the core and excessive steam production.

Steam generation in the core displaces the water liquid coolant (a process known as voiding). This is dangerous, as liquid water regulates fission by absorbing neutrons. An absence of liquid water reduces neutron regulation, resulting in increased core reactivity and an uncontrolled increase in power (i.e. a positive power feedback) as we saw in the Chernobyl accident.

Finally, after deliberately shutting down many safety systems, when the reactor operators shut down the RBMK reactor by control-rod bank-insertion (known as AZ5), the graphite-tipped control rods (a design flaw) momentarily increased the core reactivity, which resulted in an uncontrolled release in power.

OPAL Safety

The OPAL reactor avoids these design shortcomings by operating far from water boiling temperatures (37°C - 45°C). Any unwanted increase in power is kept in check by a passive reduction in reactivity (i.e. negative power feedback, which is a required design feature for all reactors – research and power - in western countries).

This is due to the change in neutron absorption with temperature of the fuel (uranium silicide) and moderation by water in response to an increase in temperature. Furthermore, the OPAL reactor is constantly monitored by an automatic safety system which will shut down the reactor if any operating parameter falls outside nominal conditions.

The safety system uses triplicated sensors and triplicated logic-trains that work independent of operator intervention, and cannot be overridden by operator action. In OPAL, there is a large reservoir of pool water to keep the reactor cool after shutdown – which means that a Fukushima-style accident also cannot happen.

Finally, OPAL operates with a negative pressure ventilation system which is designed to prevent any release from escaping the reactor building.

Media enquiries, please email media@ansto.gov.au