Published on the 17th May 2024 by ANSTO Staff

Key Points

- A biomass waste stream could be redirected to help fabricate advanced electrodes for next generation lithium sulfur batteries

- Porous carbon frameworks made from coffee-waste carbon stabilise the chemistry

- Soft X-ray spectroscopy was used to measure the stability of the battery’s chemical byproducts at the electrode surfaces

There is growing interest in use of coffee grounds to produce materials for advanced batteries. A number of recent publications have reported significant advances in the search for sustainable and efficient energy storage solutions using biomass waste streams. Read more

With over 8 million tonnes of waste coffee grounds entering landfill every year, this study highlights a biomass waste stream which may be redirected to help fabricate advanced electrodes for next generation batteries.

The University of NSW, a leading centre in recycling technologies, undertook some innovative research at the Australian Synchrotron a number of years ago on porous carbon frameworks made from biomass-derived carbon as a component in electrodes for lithium sulfur batteries.

The work was undertaken as a precursor to the ARC Microrecyling Research Hub, led by Australian Research Council (ARC) Laureate Professor Veena Sahajwalla. The Hub has been established to help transform the waste industry by establishing viable means to recover ‘lost resources’ through the research and development of novel advanced manufacturing technologies that create new pathways from low-value waste to value-added materials.

“The battery value chain is typically diverse and this can cause significant issues for manufacturers and end-users. By using waste produced at scale for battery components, industry can diversify their inputs while addressing both environmental and sustainability concerns,” said Prof Neeraj Sharma of the UNSW, a co-author on the paper.

Future batteries using lithium sulfur (Li-S) chemistry promise to deliver around ten times the capacity of the current lithium-ion technology. A critical issue which prevents their adoption is poor stability of the sulfur-containing chemicals at the battery’s electrodes; these tend to migrate away, leading to a loss of battery capacity over multiple charge and discharge cycles.

One of the ways to stabilise the chemistry in a Li-S battery is to create a porous architecture within the electrodes which helps to physically entrap the chemicals, preventing this loss of performance.

Researchers from the Sustainable Materials Research and Technology centre (Smart@UNSW) and School of Chemistry at the University of NSW in collaboration with CSIRO Clayton, identified that porous carbon frameworks made from biomass-derived or coffee-waste carbon are an attractive solution to this issue.

Not only are the frameworks electrically conductive, but they also feature a hierarchy of pore sizes to potentially optimise the entrapment process. Waste biomass is a cheap and abundant source of carbon and can be simply heated to high temperatures in the absence of oxygen (pyrolysis) to synthesise the required porous material with no further specialised treatments.

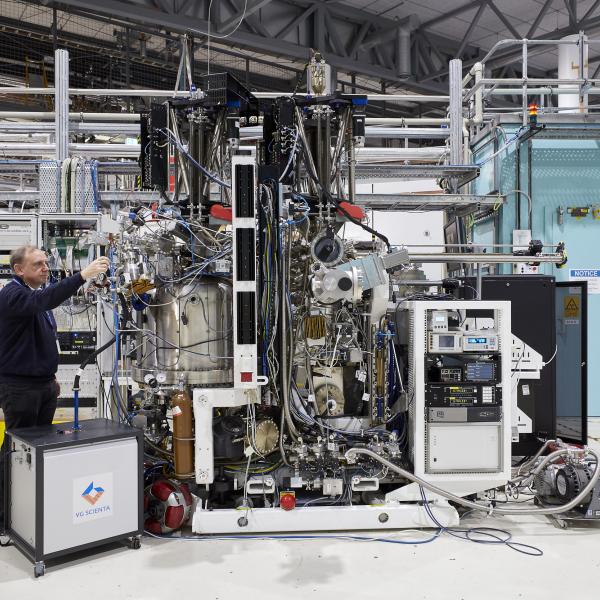

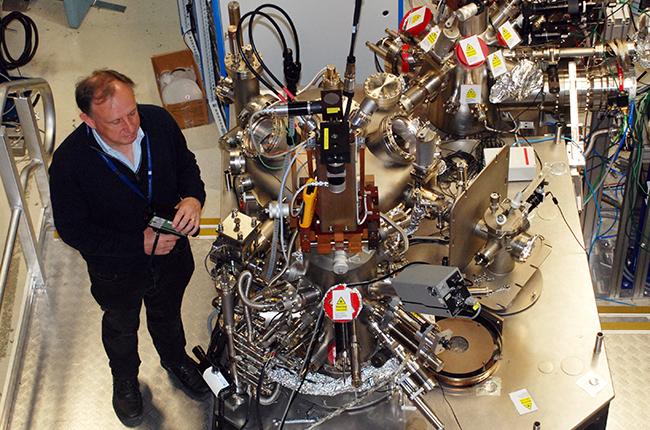

In this study, researchers investigated if pyrolysed waste coffee grounds were able to improve the performance and stability of a prototype Li-S battery. Using the Soft X-ray Spectroscopy (SXR) beamline at the Australian Synchrotron, they were able to directly measure the stability of the battery’s chemical byproducts at the electrode surfaces by studying the chemistry of carbon, sulfur and other trace elements.

Dr Bruce Cowie, a co-author on the paper published in Carbon Trends assisted with the XANES measurements on the SXR beamline.

“The SXR beamline is exceptionally surface sensitive, providing unique insights into the surface chemistry of the battery’s electrode-electrolyte interface. The team found that the electrodes which had been prepared with the pyrolysed coffee grounds exhibited a more stable chemistry,” said Dr Cowie.

This correlated well with ex-situ battery performance measurements which demonstrated 98% efficiency even after 100 charge/discharge cycles.

This article is based on a case study prepared by Dr Bruce Cowie