Published on the 11th August 2022 by ANSTO Staff

With a well-established portfolio of nuclear research and the operation of Australia's only nuclear reactor, OPAL, ANSTO scientists conduct both fundamental and applied research on fuel for current, advanced, and future nuclear technology systems.

A highly accomplished and experienced group of researchers, who contribute to ANSTO’s sovereign nuclear capabilities, undertake investigations that support the high performance of the OPAL multipurpose reactor and contribute to the international nuclear industry more broadly.

“ANSTO has undertaken research on nuclear fuel since its earliest days of operation. We are building on the contributions of a generation of researchers in materials science, chemistry and physics. This has evolved into a core capability today. Our scientists, Prof Gordon Thorogood,A/Prof Ondrej Muránsky, Dr Meng Jun Qin, Dr Zhaoming Zhang, Dr Gregory Lumpkin, and Dr Warwick Payten, are recognised internationally for their expertise,” said Prof Mihail Ionescu, Leader of Nuclear Fuel Cycle research at ANSTO.

“Our nuclear fuel research team is undertaking work on nuclear fuel that is leading to improvements in the safety and reliability of nuclear reactors. This includes the uranium oxide fuels used in most currently operating reactors and non-oxide fuels, such carbide and nitride-based fuels, and next generation fuels,” said Prof Ionescu.

Some of the research involves prestigious international partners, including the French Alternatives and Atomic Energy Agency (CEA), Idaho National Laboratory, the Generation IV Reactors Forum and the International Atomic Energy Agency (IAEA).

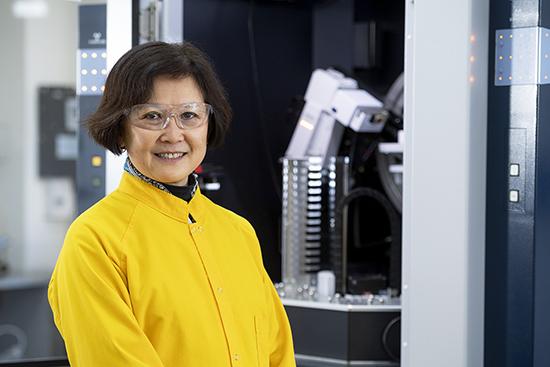

Our researchers use a range of capabilities at ANSTO for the synthesis and characterisation of nuclear materials, facilities to handle ‘active’ (radioactive) samples, analytical chemistry laboratories, instruments for investigations into structure and functional properties, and computer modelling.

“Because the properties of a material depend in large on the relative position of constituent atoms, impurities and defects, we need an understanding at the most fundamental level.”

“Even after decades of research to gain a clearer understanding of what is occurring at the atomic level, we are still learning things about nuclear fuel.”

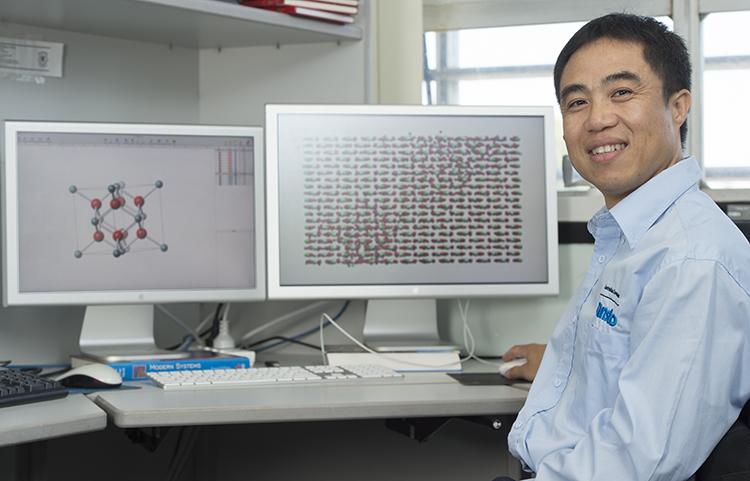

Computational and multiscale modelling is useful because it can predict the structure and properties of synthesised fuel materials and the fabrication process, as well as the properties during use inside the reactor.

“Computational models of the complex atomic structure of fuel are particularly useful and do not require the direct handling of radioactive materials,” said Prof Ionescu.

“However, we operate laboratories designed for the handling of active samples and have advance expertise in handling them, to allow in-house experimental validations of computational models.”

Our group has published a number of breakthrough studies on atomic structure with implications for nuclear fuel.

“Any predictions of structure and properties need to be validated by experimental activity, including mechanical testing, electron microscopy, neutron instruments at the Australian Centre for Neutron Scattering and X-ray beamlines at the Australian Synchrotron, as well ion irradiations using our accelerators at the Centre for Acclerator Science, electron microscopy and a specialised Gamma irradiation facility” he added.

Ion beam irradiation are used to simulate some of the changes that occur to materials over many years of exposure to neutrons in an operating reactor.

Uranium and the other actinides in fuel are subjected to extreme conditions found within reactor operating environments, such as high temperature, radiation, corrosion and pressure.

Modelling has proved to be also highly useful to the design and maintenance of engineering structures used in nuclear and other industries. This has helped to reduce design tolerances and to predict the remaining life-in-service for specific plant components, contributing to increased safety and reducing costs.

Collaborative research on materials operating in extreme environments, such as molten salt reactors, is bringing a better understanding of the degradation of materials.

Investigations of molten salt as a potential nuclear fuel are a promising area of research for Generation IV reactor designs and for use as a storage medium for renewable energy.

There is also a focus on advanced fuels, such as accident tolerant fuels, that use new materials to reduce the build-up of hydrogen, improve the retention of fission products and are structurally more resistant to extreme conditions.

Nuclear fuels for the next generation of nuclear reactors can be longer lasting, cheaper, provide more energy power, provide some recycling of previous fuel, offer easier refuelling, are easier to store and dispose of, and are proliferation-resistant.

ANSTO nuclear fuel researchers are contributing to a better understanding of inert matrix fuels (that do not contain uranium).

Plutonium-based fuels are of interest because they can obtain the highest efficiency for the elimination of excess plutonium via burning in a reactor, an important consideration for the storage of waste.

Some fuel-related projects have provided solutions to mitigate the failure of the cladding that surrounds the fuel.

Watch for Part 2 of this series later this month, which will feature ANSTO research on spent fuel.

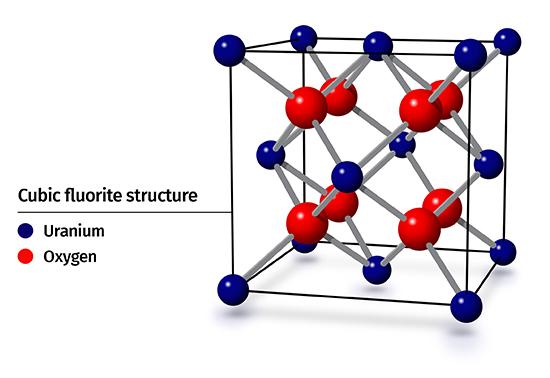

Uranium is the primary building block of most nuclear fuels

Uranium is the main fuel for nuclear reactors, although other radioactive elements, such as plutonium and thorium, can be used as a material that undergoes a fission chain reaction.

It is converted into a uranium dioxide (UO2) powder at a fuel fabrication plant, where it is compressed into small pellets and heated to form dense ceramic materials.

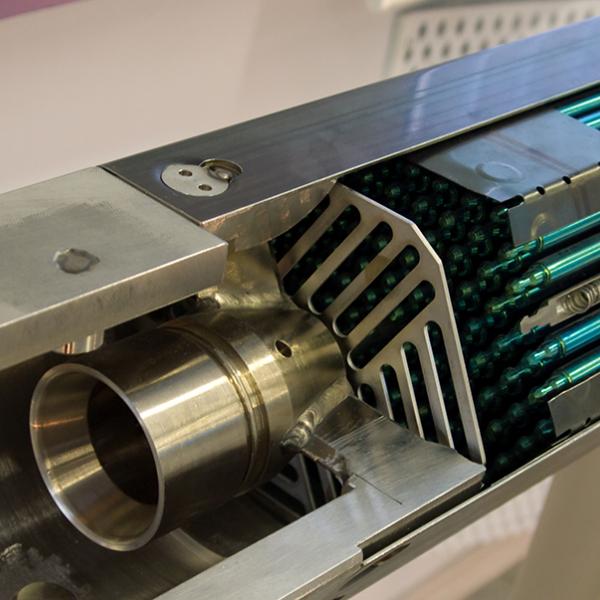

The pellets are inserted into fuel rods, usually made of a zirconium alloy, which are bundled together in a cluster to form fuel assemblies. The number of fuel rods depends on the type of reactor.

The fuel must be a robust material to withstand high operating temperatures and a radiation environment among other conditions. The fuel rods need to maintain their shape and integrity over a period of several years within a reactor core.

Nuclear fuel must have a number of physical properties, including the ability to conduct or transfer heat, heavy metal density, chemical stability and a high melting point.

Fuel cladding is the outer layer of the fuel rod that protects the fuel from corrosion and prevents the release of fission products into the reactor coolant.

Materials used for cladding do not absorb neutrons and have high thermal conductivity but not high thermal expansion.

The most common cladding materials today are zirconium alloy (“zircaloy”) and stainless steel.