Published on the 17th December 2015 by ANSTO Staff

RemLife is an innovative software tool developed at ANSTO for use at power stations to help maintain plant components and improve the efficiency of operations—including conventional power stations, combined cycle heat steam recovery boilers and nuclear power stations.

“It allows a quick and accurate assessment of component damage based on operating conditions without actually testing it in real life. Using RemLife, power stations are able to optimise operations, reduce downtime, and reduce carbon emissions,” said Materials Engineer Dr Warwick Payten, who was a key contributor to the development of the software.

“Almost all large thermal and combined cycle power stations in Australia use RemLife to manage their assets,” said Payten.

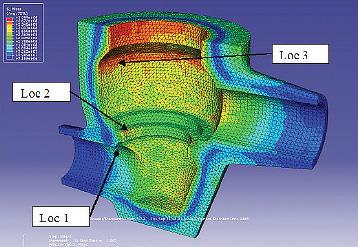

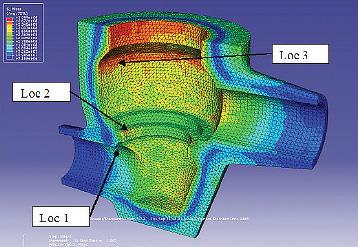

RemLife uses a combination of methodologies to perform quick and accurate analyses of the effects of high temperature and high pressure on industrial plant components.

Additionally, it can be used to compare the economic benefits of specific cycling regimes.

Engineers can determine which components are at risk due to their operational history and plan future operating regimes.

“It enables power plant managers to quickly screen a large number of components to see which ones may be at risk due to planned operations and gauge the overall operational state of the plant,” said Payten.

“Rather than spending a week assessing a single component, that assessment can be carried out in minutes,” said Payten.

Materials that are subjected to extreme pressure and temperatures undergo changes that must be monitored.