Published on the 8th May 2020 by ANSTO Staff

Key Points

- An additive manufacturing technique, laser cladding deposition, has the potential to enhance safety and significantly reduce maintenance on rail transport systems and beyond

- Funding from an Australian Research Council Linkage Project allows Monash University, industry partners and ANSTO to undertake the research

- The purchase of a laser cladding deposition system with funding from NSW state government, NCRIS and ANSTO allows the investigators to study the materials on neutron instruments while the technique is being used

ANSTO will contribute to an Australian Research Council Linkage Project that was announced recently to develop an additive manufacturing technology, laser cladding, to maintain rails in train networks.

The research has the potential to significantly reduce rail maintenance costs and enhance safer transport.

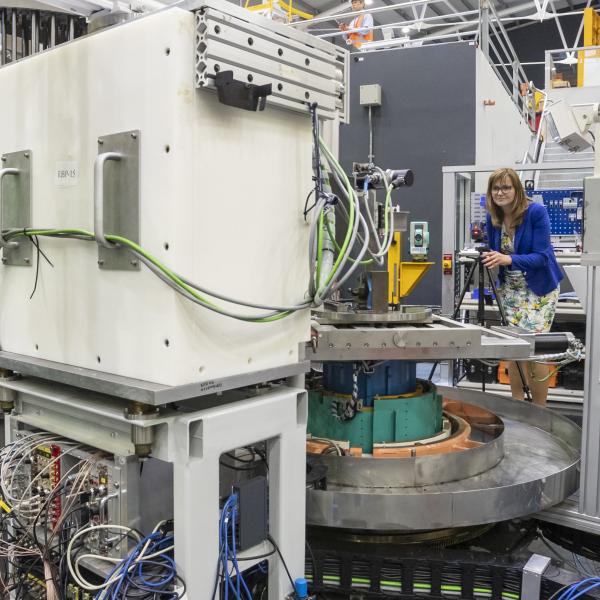

Industry Engagement Manager Professor Anna Paradowska (pictured above) will be a principal investigator on the project, which is led by a team from Monash University under metallurgical expert A/ Professor Ralph Abrahams with an industry partner, Laserbond Limited. Yarra Trams is involved as a partner organisation and will assist with in-service evaluations of the technology.

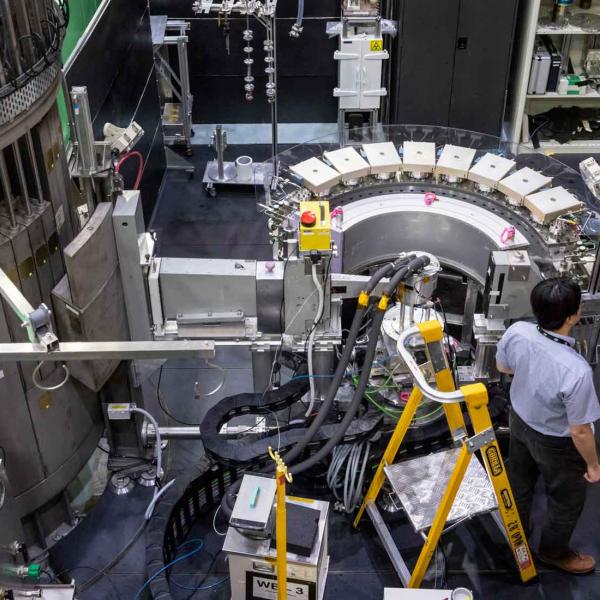

Investigations on ANSTO’s materials and engineering beamline the strain scanner Kowari at the Australian Centre for Neutron Scattering will provide measurements of residual strain and residual stresses on materials that have been repaired using the laser cladding technique.

“We expect to use Kowari to determine the residual stresses within the interior of bulk material and a range of investigations of structural integrity. I have considerable experience in collaborative investigations of laser cladding repair techniques for application on rails, aircraft and mining components,” said Paradowska.

The high-intensity diffractometer Wombat will be available for texture studies as well as the neutron tomography instrument Dingo for defect assessment.

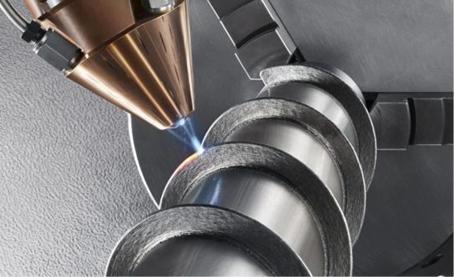

The laser cladding technique uses laser energy to melt a metal alloy powder, which is injected into the surface of the component and bonds the cladding in a metallurgical process to the surface of the part.

The project aims to develop a new cost-effective maintenance technique based on this innovative and interdisciplinary technology to enhance the characteristics of new rails and track components and repair damage to ensure structural integrity and improve performance.

It will enable manufacturers and operators of railway networks to develop and improve railway maintenance strategies. Other benefits include extending the service lives of rails and special track components, reducing wheel squeal and flanging noise.

The investigators said the research addressed a National Research Priority in that it can maximise Australia’s competitive advantage in the critical infrastructure sector. Both the state and federal governments have made railway infrastructure a national priority for investment.

Specifically, the project will select the most suitable materials and processing parameters for laser cladding on tram switch blades and wing rails based on laboratory research, optimise the design of laser cladding repairs for blades and rails and carry out full-scale field tests of the technology under service conditions.

Australia has the 7th longest rail network in the world at more than 40,000 kilometres.

Contact between steel wheels and steel rails can lead to degradation and rail breakage.

Existing repair protocols, based on a variety of types of welding, such as electric arc welding, can make the rails vulnerable to crack initiation, high tensile residual stresses and increased thickness in repair zones requiring frequent replacement.

Many studies, including some leading work by the Monash group, have investigated new and better rail repair techniques, including laser cladding. Monash previously investigated the applicability of using laser cladding to repair high strength steel used in Australian heavy haul railways and confirmed its ability to enhance wear and resistance of the steel.

The research is expected to have benefits beyond the rail industry to a large variety of industries that require good wear resistance, corrosion resistance and temperature resistance, such as the power supply sector.

Laser Deposition System grant

A key capability for this research which has been secured by ANSTO is an in-situ laser deposition system. The NSW Government recently awarded a Research Attraction and Acceleration Program Grant of $140,000 towards the purchase of a laser metal deposition system, with additional funding contributions from the National Collaborative Research Infrastructure Strategy (NCRIS) and ANSTO.

“The advantage of having the system is that it enables us to do in-situ neutron scattering measurements and imaging, while the laser cladding process is being performed,” said Dr Jamie Schulz, Leader, Australian Centre for Neutron Scattering.

“It will provide information in real-time about the deposition and solidification processes that occur using this additive manufacturing technique.”

“In turn, this information will allow us to make recommendations to optimise the process for the rail infrastructure project,” said Schulz.

The system includes a laser head, powder feeder with associated equipment, including a chiller and power supply.

For setup on the Kowari strain scanner, the system needs motion stage and control, suitable shielding and integration with instrument control software.