Published on the 19th November 2021 by ANSTO Staff

Researchers from the University of Wollongong have improved a high voltage cathode material to deliver structural stability and an unprecedented electrochemical performance for lithium-ion batteries (LIBs) in work that is extendable to other types of energy storage materials.

The material, LiNi0.5Mn1.5O4 (LNMO) is one of the most promising candidate materials to replace the material LiCoO2, because of a high energy density, low fabrication cost, and low environmental impact.

However, an unsatisfactory cycling performance and structural instabilityin LMNOhas limited its wider application and further commercialisation.

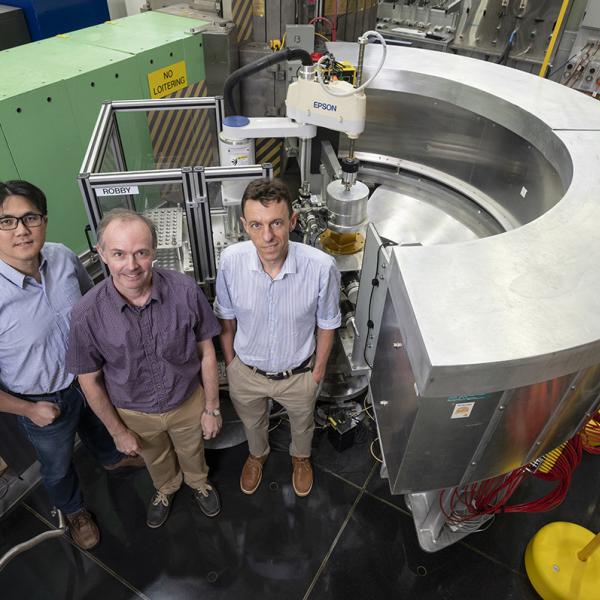

Dr Wei Kong Pang of the University of Wollongong leads a team, who have published a study that has investigated how to overcome inherent challenges associated with using LNMO as a cathode electrode material.

Instability in cathode materials can intensify as the energy density increases, which can affect the reliability and safety of the battery.

Prof Vanessa Peterson, Senior Principal Research & Instrument Scientist at ANSTO’s Australian Centre for Neutron Scattering and Project Lead on Energy Materials and Honorary Professorial Fellow Institute for Superconducting and Electronic Materials University of Wollongong, collaborates on batteries research with the Wollongong group.

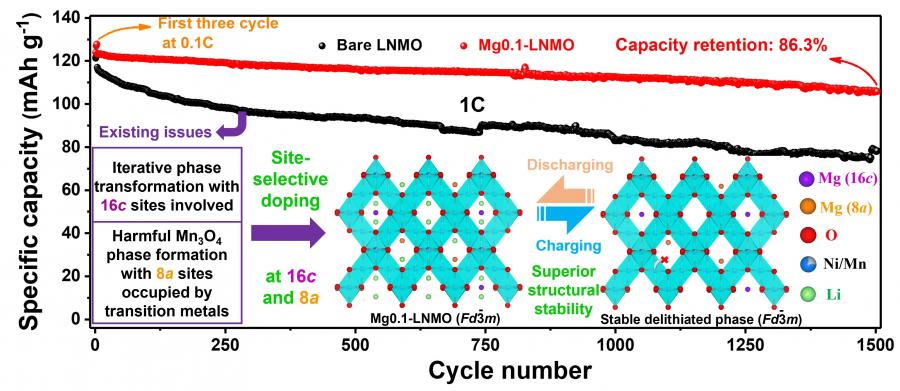

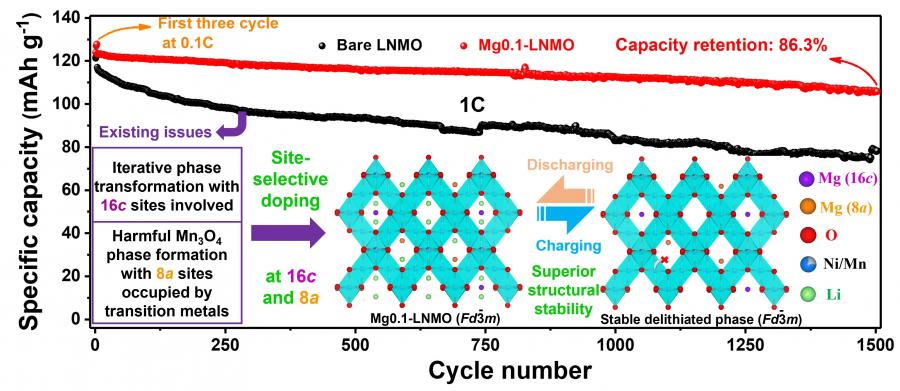

To overcome intrinsic properties linked to the structural coordination in the material, the researchers added manganese atoms at specific sites in the disordered spinel configuration unit cell.

They found that doping stabilised the structure against deformation and suppressed unfavourable chemical changes during cycling.

“The doped material delivered an extraordinary battery performance. An electrical capacity of over 87 per cent was retained after 1500 cycles,“ said Pang.

“This doping technique demonstrated how structural engineering of the crystal can deliver a fit-for-purpose material.”

“Only cathode materials that exhibit high energy density, high-rate capability, low cost, and stable cycling performance can meet the needs of the next generation LIBs,” said Pang.

Using this type of battery in a cell phone or a power tool would result in a 5-year battery lifetime with a daily recharge.

Because LNMO materials have a high voltage working capability and an energy density that is 30% higher than current lithium-ion batteries, they may also be suitable for high-energy applications, such as vehicles.

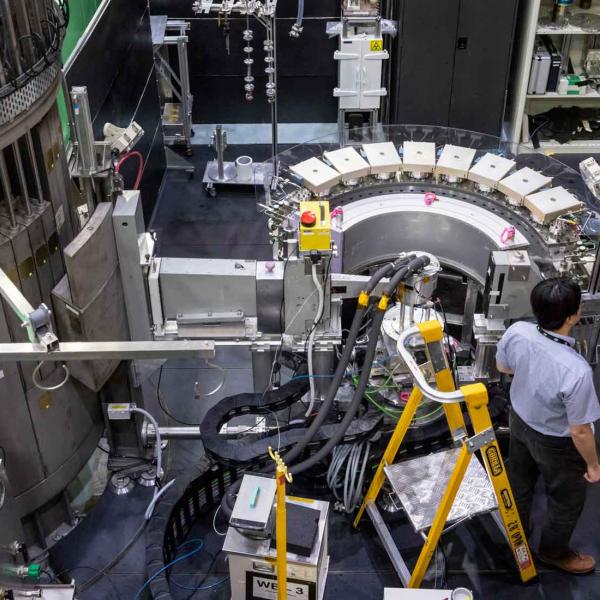

Neutron scattering experiments on the Wombat High-intensity diffractometer and Echidna High-resolution powder diffractometer instruments at ANSTO’s Australian Centre for Neutron Scattering were used to characterise the advanced material and confirm that the atom site-specific engineering successfully stabilised the structure during charging and discharging the battery.

“Neutrons are essential for studying battery electrode materials,” said Pang.

"Neutron diffraction is sensitive to the lighter oxygen and lithium atoms but can also differentiate between metals, such as nickel and manganese, used in battery materials; something that other techniques struggle to do."

The neutrons can also penetrate the bulk of industrial-sized batteries.

The technique is used to determine the arrangement of different elements within the material structure.

The results of this work were reported in Chemical Materials in February this year, as well as the team reported on the performance of a series of dopants in an article published in Angewandte Chemie-International Edition in 2020,

This research was selected as the winner in ANSTO’s Neutron and Deuteration Impact Awards, demonstrating relevance to energy, one of Australia’s research priorities.