Published on the 19th March 2019 by ANSTO Staff

ANSTO will collaborate with the NSW Department of Roads and Maritime Services (RMS) and researchers from the Australian National University, University of Sydney and University of Canberra, on a project to use advanced laser cleaning on the iconic Sydney Harbour Bridge.

The project which is being led by Prof Andrei Rode from Australian National University has just been awarded an ARC linkage grant of approximately $858,000 over 3 years, will develop novel laser-based approaches to large scale processing of corroded metal and dirt-encrusted stone surfaces.

The technology uses a new class of powerful industrial ultrafast lasers.

“This is a big cleaning job that we are happy to be involved with," said Dr Jamie Schulz, Leader, Australian Centre for Neutron Scattering.

The lasers provide higher throughput, substantially reduce the heat load to the structure, reduce energy costs and improve the control of the characteristics of the surface following treatment for better long term conservation.

The new techniques will offer improved safety and economic benefits in building maintenance as well as scrap reduction for the marine, automotive and aircraft industries.

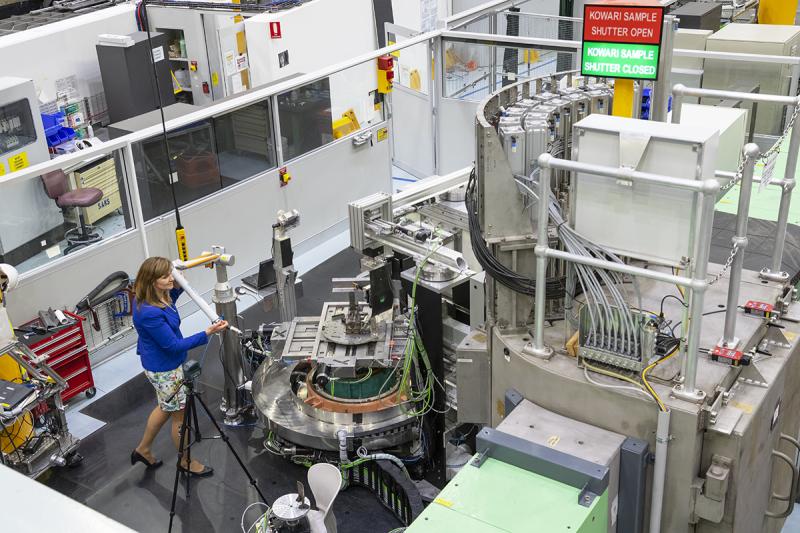

ANSTO’s contribution as a Principal Investigator, through the Australian Centre for Neutron Scattering (ACNS) and Nuclear Materials Development and Characterisation (NMDC), will involve undertaking stress assessments to materials using X-rays and neutron diffraction techniques.

“In this project, the team will be analysing the mechanical properties of the laser treated steel and granite material for fatigue resistance, surface roughness, determine the microstructure, resolve the distribution of residual stresses and micro-cracking,” said Dr Anna Paradowska, ACNS Industrial Liaison Manager.

“In addition to our experience with structure integrity, ANSTO has unique capabilities and a wealth of experience in testing and characterising the relationship between structure and properties in a material,” said Dr Michael Drew, Senior metallurgist, NMDC

The Sydney Harbour Bridge is approaching its 90th Anniversary. Current conservation work involves sandblasting dirt, rust and the existing lead-based paint and applying lead-free paint to protect the structure.

A different approach is needed for 7.2 kilometres of tightly confined tunnels, which are inaccessible to humans and sandblasting creates too much dust. In contrast, powerful ultra-short pulse lasers can be used with minimal dust and waste for cleaning.

The conservation strategy includes the development of a practical robotic system to undertake inspections, carry out cleaning, re-paint and remove waste.

The long term goal of developing effective laser removal processes and reconditioning has the potential to maintain the integrity and original views of the bridge.

The new laser techniques should prevent detrimental damage to the cleaned surfaces, such as residual stresses, micro-cracking or roughening that decreases structural performance and surface integrity.

Laser cleaning has been used widely to remove contamination from historic architecture when traditional methods are not viable.

“We are very excited that we can utilize ANSTO unique capabilities and expertise to help develop technology that will help maintain Sydney Harbor Bridge - an iconic image of Sydney, and Australia itself!” said Paradowska.

ARC Results