Key Points

-

Understanding how materials will perform in extreme environments is crucial to the development of new energy technologies, Australia's defence capabilities and space exploration

-

ANSTO are leaders in the characterisation of materials from the atomistic to macroscopic scales. This is needed to fully understand performance and service life in extreme environments

-

ANSTO has world-leading infrastructure and materials research expertise to characterise materials for extreme environments

ANSTO researchers investigate how materials behave in extreme environments, providing information that is vital to support the development of our industries.

Extreme environments include situations where materials are exposed to a combination of different conditions, including high temperature, radiation, corrosion and mechanical load.

How materials respond in these environments helps to identify what materials are best for certain industrial environments or for example, within a nuclear setting such as new nuclear power plants.

“In fact, the technical performance of materials is one of the greatest challenges in improving the safety, efficiency and economic viability of nuclear systems”, said ANSTO Principal research scientist A/Prof Ondrej Muránsky.

However, the testing of materials in extreme environments, such as a combination of high-temperature, corrosion and radiation is not trivial in laboratory conditions, as it requires substantial infrastructure.

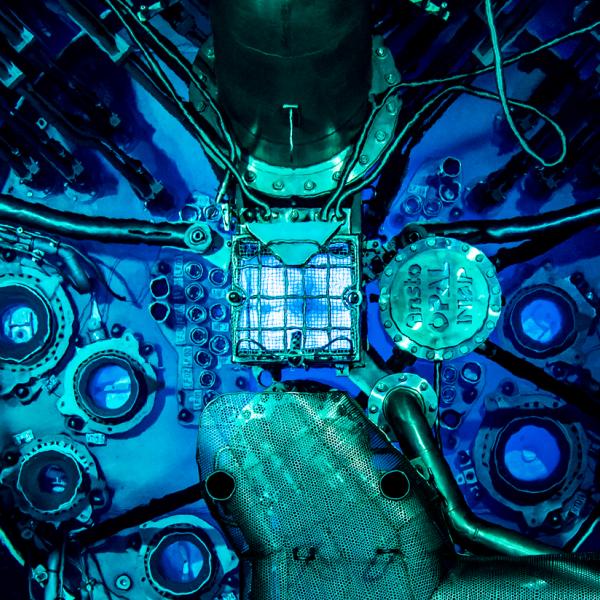

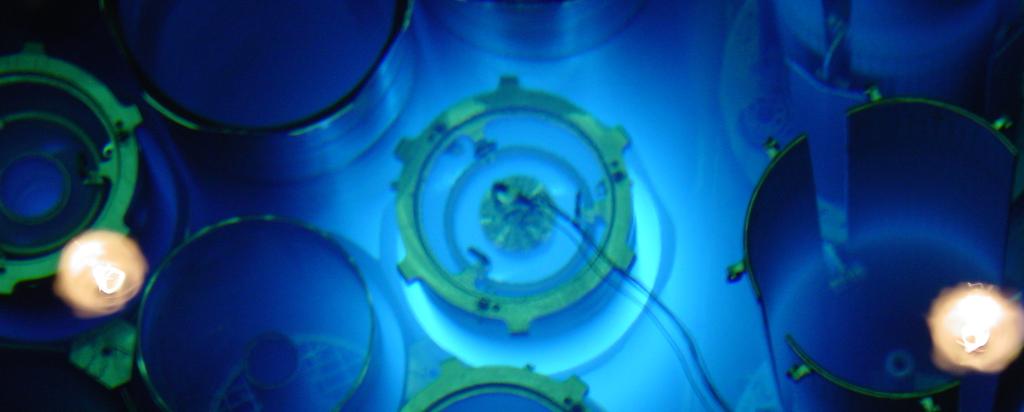

ANSTO is home to Australia’s nuclear expertise and operates its only multipurpose reactor OPAL and is ideally positioned to study the behaviour of materials and degradation in extreme conditions combining various in-service environments.

“ANSTO’s research infrastructure and in-house expertise, in particular the work of the Reactor Systems research group, enables us to build a holistic understanding of the fundamental and applied aspects of materials in extreme environments,” said Muránsky.

When studying materials behaviour in extreme environments, we need to keep in mind that materials are multiscale systems. Therefore, we need to apply multiscale experimental and numerical techniques to fully understand their degradation and ultimately the failure – from atomistic scale to macroscopic scale.

“Knowing that a piece of material has failed at the macroscopic scale has limited value until you analyse the underlying degradation and failure mechanism which may be occurring to the atomic structure,” said Muránsky.

ANSTO uses diffraction (neutron/synchrotron) and various microscopy techniques available at its campuses to probe a material at different scales in various environments.

This experimental data is then combined with state-of-the-art modelling approaches to simulate a material’s response from the atomic to the macroscopic scale.

A fundamental understanding of the material’s behaviour from experimental data can be used to build and validate physically based, empirical or/and machine learning models, which help to predict the behaviour of materials in extreme in-service operating conditions in a real-world engineering system.

ANSTO’s work on building a multiscale understanding of materials behaviour in extreme environments has a multiindustry significance, as it is relevant not only to the energy industry, but it is also important in the defence and emerging space industries.

Recent work has been on molten salt reactors and their corrosive environment, which also has applications for the molten salt-based energy storage and transfer systems for solar.