Published on the 28th June 2024 by ANSTO Staff

A team of researchers from ANSTO and University of Technology Sydney have set a record by conducting thin film experiments at 1100o C, using the Spatz reflectometer equipped with a vacuum furnace.

The unique combination of neutron reflectometry with high temperature apparatus enables atomic-scale insights into thin film growth and diffusion processes. This is of relevance to a wide range of thin film technology and devices which undergo a range of processing and heat treatment conditions to optimize performance.

The UTS group, led by Francesca Iacopi and Aiswarya Pradeepkumar, has been studying the growth of thin carbon sheets (graphene) on SiC/Si substrates which occurs at high temperature. This award-winning process allows for highly conductive electronics that can be integrated with standard silicon fabrication processes.

To better understand the carbon growth mechanisms and onset temperatures, the UTS team made extensive use of the Spatz neutron reflectometer at the Australian Centre for Neutron Scattering.

Neutron reflectometry allows thin films in the thickness of 1-100 nm to be studied. Because of the unique characteristics of neutrons, studies can be performed in-situ in advanced sample environments, in this case, a sophisticated vacuum furnace to observe film changes on the timescale from minutes to hours.

Dr Aiswarya Pradeepkumar, a research fellow within the ARC Centre for Transformative Meta-optical Systems, and a recipient of the Australian Institute of Nuclear Science and Engineering (AINSE) Early Career Grant, led the ANSTO-UTS collaboration which was the first experiment of its type in Australia. The research was published in RSC Advances, and subsequently highlighted in an article for Neutron News this year.

“The unique high-temperature neutron reflectometry has allowed us to gain insights into the alloy-mediated epitaxial graphene synthesis on 3C-SiC/Si substrates unveiling novel avenues of 2D material optimisation for nanoelectronic and nanophotonic applications,” said Dr Pradeepkumar.

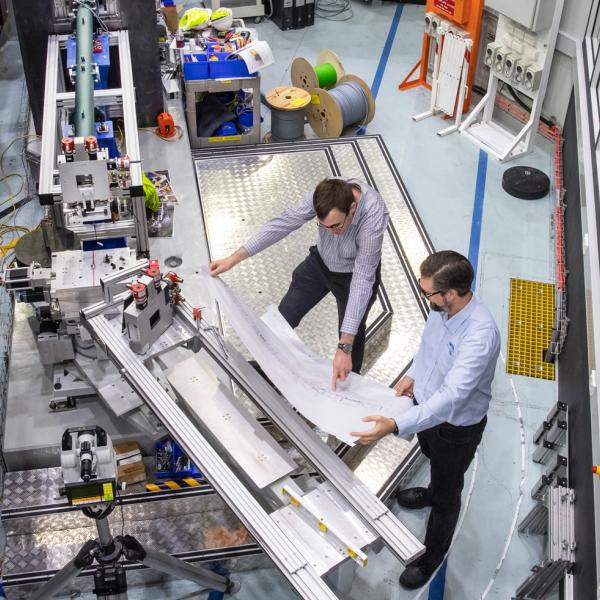

Two ANSTO scientists, Dr David Cortie and Dr Anton Le Brun, enabled the research at ANSTO by integrating the furnace with Spatz.

The Neutron Scattering Sample Environment and Scientific Operations team supported the process by integrating the furnace onto Spatz and fabricating the special sample holders. Both were essential to the success of the experiments.

“To the best of our knowledge, this is the highest temperature neutron reflectometry study that has ever been recorded, and it is a relatively unique capability internationally,” said Dr Le Brun.

“It follows from some pioneering work done by Holt and colleagues at the ISIS Pulsed Neutron Source in England in the late 1990’s.”

The Spatz instrument was transferred from HZB Berlin and configured at the Centre in 2020. The large open plan nature of the instrument allows it to accommodate a range of larger sample environments.

“I am really excited by the new opportunities for high temperature reflectometry work,” said Dr Cortie.

“This capacity will allow a range of important thin film processes to be studied with neutron reflectometry for the first time, to reveal nanoscale insights that are hidden from many other probes. There are already a number of related thin film studies underway at the Australian Centre for Neutron Scattering.”

https://doi.org/10.1039/D3RA08289J

Thanks to Dr David Cortie for preparing the report.