Multiscale modelling of laser-based additive manufacturing for the development of process–structure–property relationships

ANSTO is working with the Swinburne University of Technology, Royal Melbourne Institute of Technology (RMIT), RUAG Australia Ltd., and DST Group on the development of multiscale numerical simulations of Laser Metal Deposition (LMD) 3D printing.

LMD is an additive manufacturing (AM) process utilising a laser beam to form a pool of liquid metal on the surface of metallic substrate into which metal powder is injected— forming a deposit on the substrate after solidification. In comparison to powder-bed techniques, LMD allows for a much higher deposition rate used in building and repairing larger engineering structures in energy, aerospace, and defence applications.

Despite the major advantages of additive manufacturing, there is, however, a continuous need to develop a full understanding of the relationships between process, structure and properties. An in-depth understanding of processes taking place during manufacturing can address a long-standing challenge to reduce the failure of a component or a repair due to the residual stress field, extensive distortion, or microstructural defects.

A multiscale physics-based modelling framework is required to elucidate the interrelationship between additive manufacturing parameters and microstructure, which governs the properties of additively manufactured components or repairs.

The main emphasis is on the development of an in-depth understanding of the effects of a large number of process variables on the ongoing metallurgical processes (such as grain growth, segregation, defect formation, etc.), residual stresses, distortion which affect resulting mechanical properties. All are crucial for any in service applications.

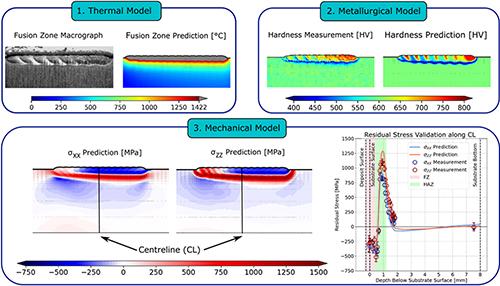

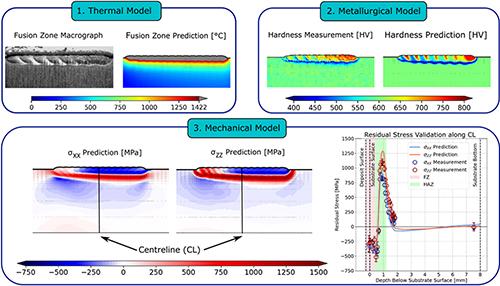

ANSTO is developing high-fidelity multiscale physic-based simulations capturing thermo-physical, thermo-metallurgical and thermo-mechanical processes taking place during the additive manufacturing process.

The models will help in understanding of the process–structure–property relationship and assist with the rapid optimisation of the LMD process for various applications.

The goal of the project is to develop validated numerical models which can assist a large range of industries wishing to utilise additive manufacturing processes for the build or repair of engineering components.

The full research article can be found here: https://doi.org/10.1016/j.ijpvp.2024.105261