New flow chemistry capability to enhance NDF production capacity

Published by NDF staff, 3rd March 2025

Flow chemistry can lead to increased efficiency, increased production capacity and reduce decomposition in the synthesis of deuterated molecules.

The National Deuteration Facility (NDF) synthesises a variety of deuterated molecules using chemical techniques, with the primary method hydrothermal deuteration and heavy water (D₂O) as the deuterium source. This process typically requires metal catalysts such as palladium or platinum at elevated temperatures.

Deuterium-labelled compounds are pivotal in pharmaceutical development, metabolic studies, and materials science due to their distinctive properties. In drug discovery, deuterium substitution can enhance metabolic stability and prolong half-life, leading to the development of "deuterated drugs" with improved pharmacokinetics. Beyond pharmaceuticals, deuteration plays a crucial role in neutron scattering contrast variation, NMR spectroscopy, and isotopic labelling for elucidating complex reaction mechanisms.

Traditionally, the high temperature deuteration reactions (>140 °C) are conducted in Parr reactors to manage the high pressures involved, but many functional groups are unstable under such conditions. However, batch deuteration is labour-intensive and limited in scale, making flow chemistry a potential alternative for large-scale synthesis.1 Flow chemistry could also improve selectivity and minimize decomposition by controlling reaction time and temperature more precisely. Flow chemistry may also offer a more efficient approach to these reactions, particularly in deuterium labelling for analytical and medicinal applications.2

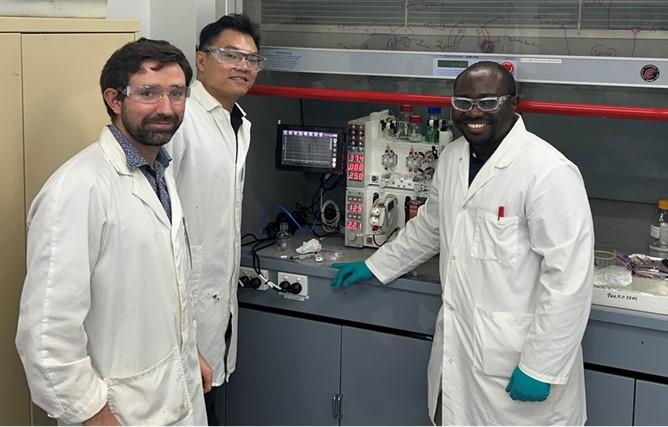

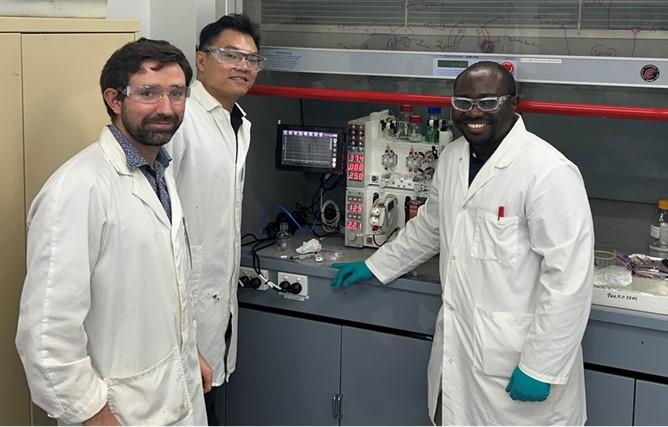

The National Deuteration Facility has recently acquired a Vapourtec flow reactor integrates real-time monitoring, streamlined processing, and flexible productivity, thereby advancing the field of flow-based deuteration. The capability development is being led by chemist Dr Jim Mensah. These capabilities not only facilitate the adaptation of established batch processes to continuous flow for multigram-scale synthesis but also encourage the exploration of novel deuteration methodologies. The increasing patronage of flow chemistry devices and methods in modern synthesis laboratories suggests that flow-based chemistry is poised to unlock the potential of flow-based organic synthesis. This work is supported by NCRIS Uplift funding received in 2023 Phase 2 funding for expansion of existing capabilities and development of new capabilities.

Chemists Michael Moir, Sek Choong Tan (Vapourtech) and Jim Mensah during the installation and commissioning of the Vapourtec flow chemistry system.

References:

1. K. Tatoueix, M. Lepron, C. Barboux, M.-C. Scherrmann, G. Pieters, S. Feuillastre, Unlocking the potential of hydrogen deuterium exchange via an iterative continuous-flow deuteration process, Nature Communications, 16 (2025) 1314.

2. F. Minya, Á. Mészáros, E. Csizmadia, D. Suskó, M. Raji, G. Sipos, Raney Nickel‐Catalyzed Deuterium Labeling of Nitrogen‐Containing Heterocycles and Pharmaceuticals under Continuous Flow Conditions, Advanced Synthesis & Catalysis, (2024).

Enquiries

Please direct any enquiries to Tamim Darwish, NDF Leader

Dr Tamim Darwish

Acknowledgments

The National Deuteration Facility is partly supported by the National Collaborative Research Infrastructure Strategy – an initiative of the Australian Government.

Enabled by