Published on the 29th October 2024 by ANSTO Staff

Before an aircraft can take off, the pilot must go through a detailed checklist before accelerating down the runway.

Before you withdraw the control rods and start a nuclear reactor, there is also a sequence of actions to follow and set of conditions to be met.

ANSTO recently restarted the OPAL Reactor after a six-month shutdown for essential maintenance and the installation of an upgraded facility. Read more

Reactor operators and shift supervisors, including Shift Engineer Simon Thomas, complete this startup sequence routinely to achieve criticality. Read more about fission.

Criticality refers to the state in which a reactor has achieved a self-sustaining a nuclear chain reaction.

The concept of criticality, when used by nuclear professionals, does not imply things are at a precarious stage. It means the reactor is operating at a defined and controlled state.

“You can’t just flick a switch to start a reactor. Detailed inspections and safety checks come first. Every part of the reactor is examined to make sure it's in top condition,” explained Simon.

"We also refuel the reactor and start up all the supporting systems as part of the startup process."

"Then, we test the safety systems and slowly bring the reactor back to life—starting at low power.”

Highly skilled reactor operators check everything at every stage to ensure the reactor is performing as expected.

"Once we’re confident that everything is stable, operators slowly increase reactor power in stages from 5 MW up to full power”.”

“Reactor power in this context refers to the level of heat produced by the reactor. For OPAL, full power is 20 MW.

Routinely, a reactor startup is scheduled over a day but following this six-month shutdown, and with the installation of the new facility, a cross disciplinary team took several days the restart the reactor.

The start of a nuclear reactor is dependent on special characteristics of reactivity, that is how much the reactor is deviating from criticality.

Understanding reactivity is crucial for controlling the operation of a reactor. The fuel, control rods and other parts of the reactor contribute to reactivity.

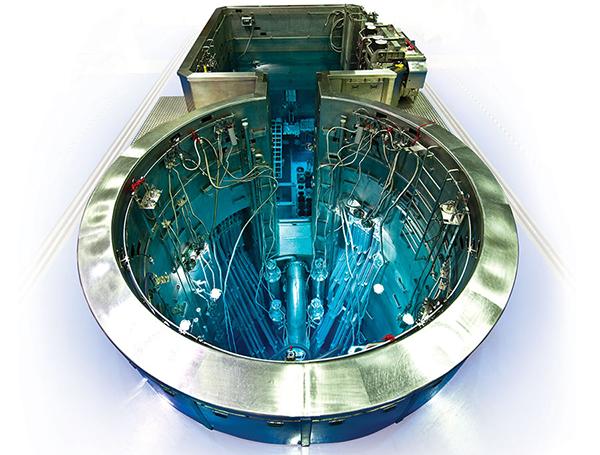

The reactor core is located in a 13-metre-deep pool. The operating characteristics of the core are measured and verified against pre-calculated core calculations.

ANSTO’s Nuclear Analysis Section is responsible for performing detailed computations to analyse the reactor physics of the reactor core.

But it is the control rods that are most crucial in the startup process and all operations.

"At OPAL, we have five control rods made primarily from hafnium, a special material which absorbs the neutrons created by fission and slows down the nuclear chain reaction. The rods allow us to control the reactor’s power."

"Think about control rods like the throttle and brake on a car. When we insert them, they absorb more neutrons and slow the fission process. If we need more power, we pull them out slightly to let more neutrons trigger reactions."

"And in less than a second, the control rods can automatically drop all the way in to shut down the reactor completely if needed.”

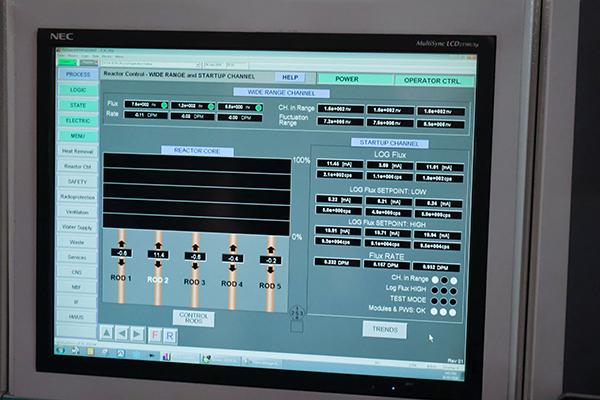

All operations are managed from the control room. A video monitor delivers live footage of the core in the pool. Observation windows allow operators to observe what is happening on the reactor floor. However, it is the vast array of instruments that provide the data on how the performance of plant and equipment.

During a reactor startup, the main control room is usually very quiet. The only sound you might hear is the reactor operators pushing buttons to move the control rods. Staff will share verbal confirmation of system checks, as would occur in the cockpit of an aeroplane.

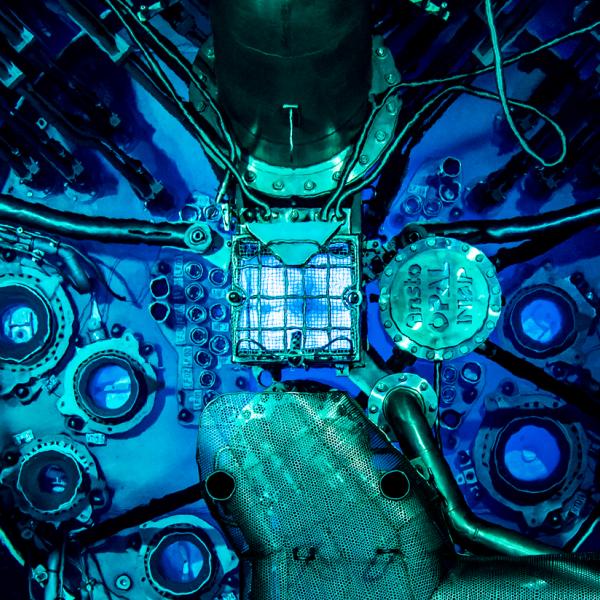

There is no actual sound from the core when the reactor is restarted, but a luminous blue glow known as Cherenkov radiation, is emitted.

This occurs when the electrically charged particles, the electrons and protons in atoms move at speeds faster than that of light in a specific medium, such as water in a reactor. Read more

"The reactor control and monitoring system tracks over 5,000 signals. This allows us to monitor critical parameters like temperature, pressure, and flow rates in real time."

"When these parameters are steady, we know the reactor is operating smoothly. It’s like watching your instrument readings flying a plane to confirm altitude and attitude."

"In addition, OPAL has two independent reactor protection systems that are always monitoring.”

"Routine safety checks ensure the reactor core is behaving as predicted, if either of the two independent Reactor protection systems identify any abnormal operation, then they will initiate an automatic and immediate shutdown.”

When the reactor was back operating after the staged restart, the reactor group, nuclear analysts, safety personnel, representative of the regulator, and others could sit back and congratulate themselves on a job well done.

“We didn’t start clapping but there were some big smiles in the room,” said Simon.

Next week we will feature the crucial contribution of the nuclear analysis team in the CNS project and reactor restart.